Deliver Phaser

Design 100

Prototyping and iteration

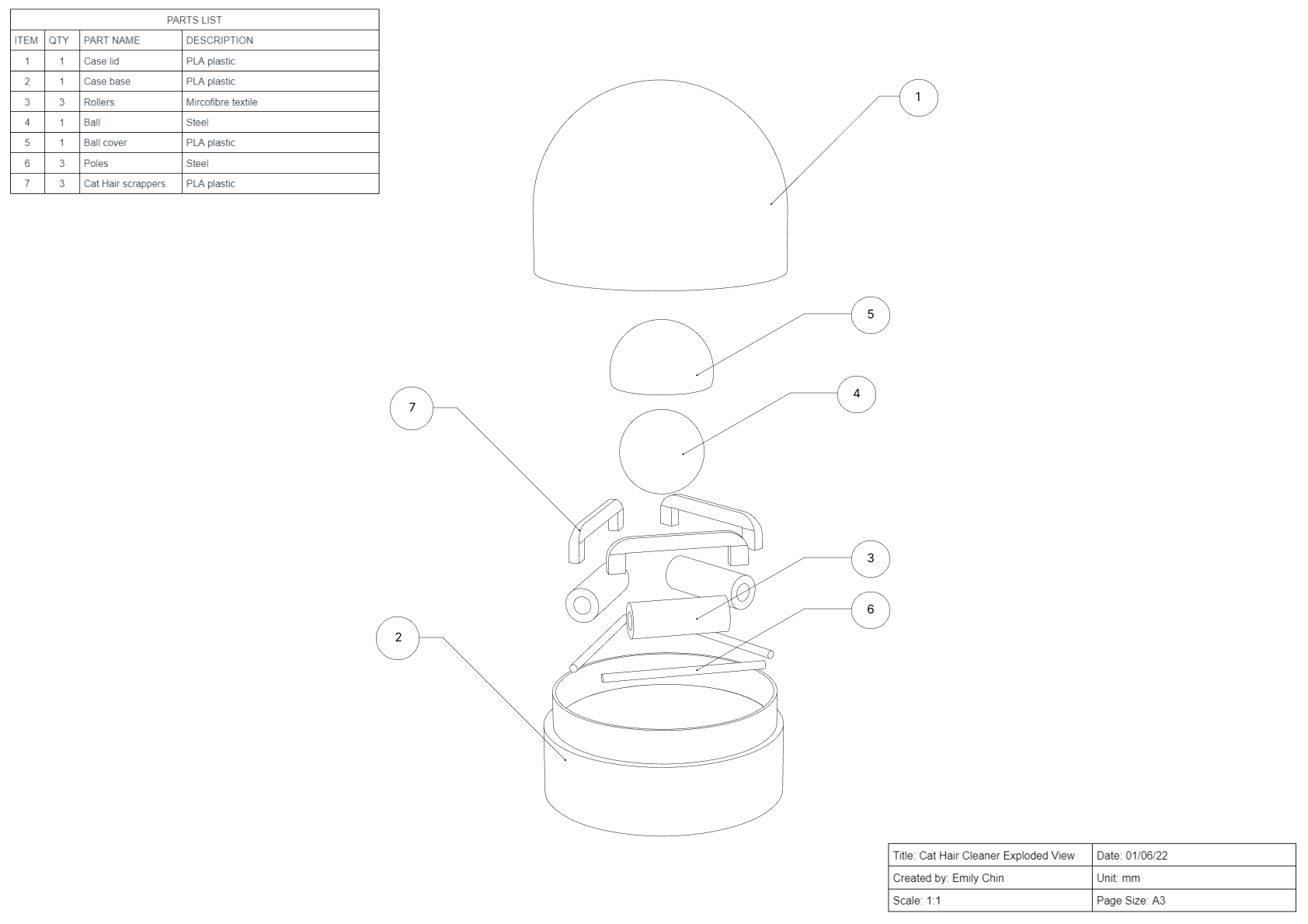

I had started the deliver stage by iterating the two prototypes I had selected in Rihno7, as having the model made in a 3D space helped made iterating much quicker and easier.

I started by modelling each of the prototypes separately and then started combining them together.

.png)

I had liked how the combined prototype allowed for the shape and look of the robot vacuum, however, it also made it so that the product wouldn’t be an electric product with the mechanism of the brush/lint roller brush implemented instead of a vacuum.

I had iterated the design with scaling of each of the parts, as well as changing the number of rollers as I had initially had 4 rollers, but I had changed it to be 3 rollers as it allowed for more space and larger rollers, but still allow the collection of cat hair in any direction.

The cat hair collection was then prototyped to make sure the product worked. I had quickly created rollers with microfibre fabric, a textile that picks up cat hair in one direction and releases it when rolled in the opposite direction. Having three rollers had worked and so I started to create my final model.

.png)

I 3D printed the outside casing of the model that was made in Rihno7.

.png)

I then made each of the rollers multiple times to ensure I had to correct size and length and placed them inside the model.

Final Model

.png)

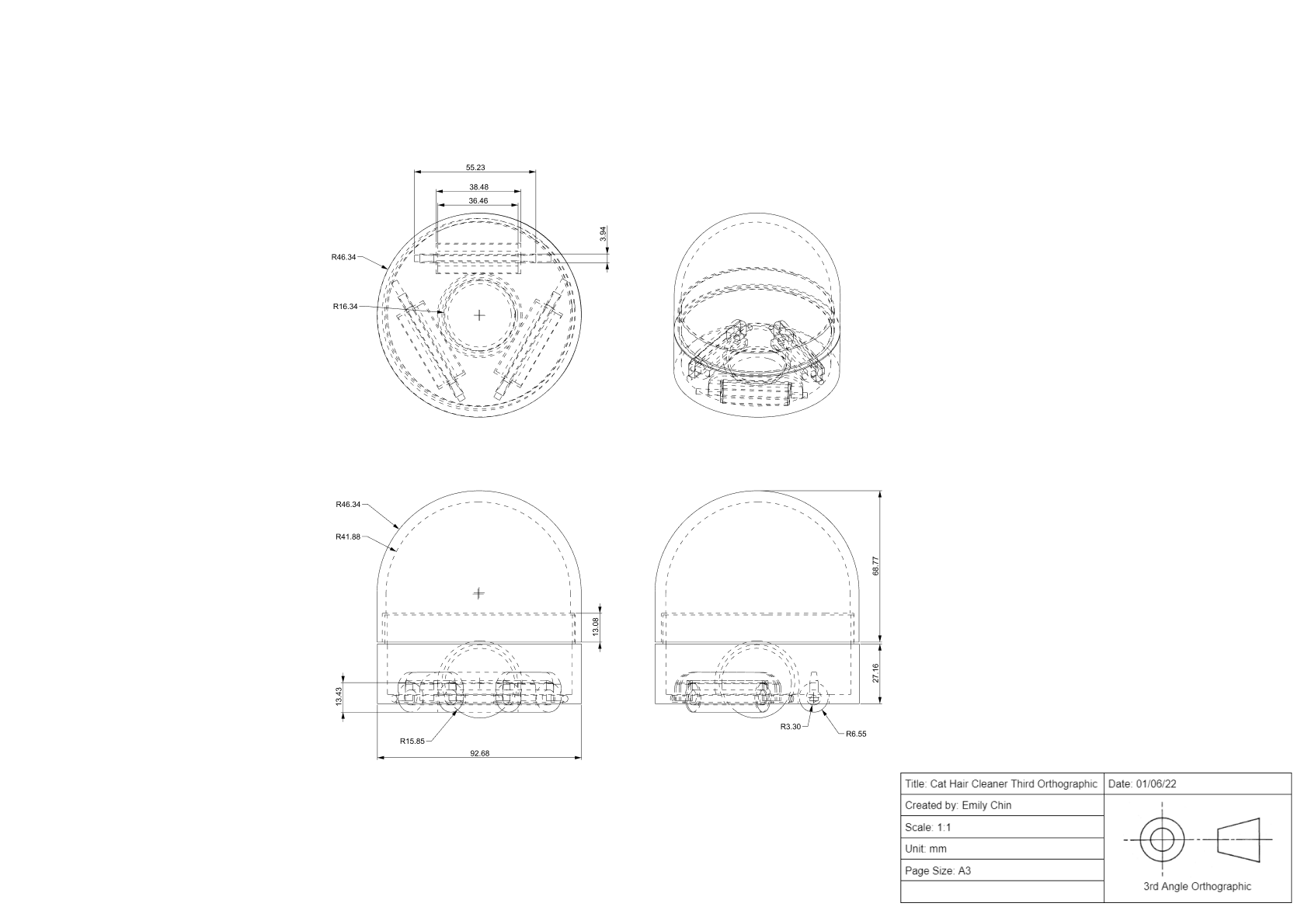

Specification drawings of the final model

Presentation Powerpoint on the model

Other Improvements

When iterating on the design, I tried to make the product more effective in a manner that would allow the user to clean the cat hair without as much physical effort. This was in the form of making the product rollable, something that could be pushed around by the user with ease or even with the cat. However, the final physical model isn’t light or smooth enough for it. Improvement could be made by making the model lighter with the choices of materials. The ball within the model was a hand-shaped clay ball, which isn’t as smooth of a material that could be used and so this could be replaced or sanded down a lot.

When rolling the model on some of my textiles, I found it got caught on some surfaces, due to the extra 3D printing on the sides. This too could be improved by sanding down the edges of the model or remodelling the base with a rounded edge.

.png)

Reflection

When comparing my design with the how might we statement created and pre-existing solutions such as a one-use lint roller. The design I produced is more attractive, as it hides the visual of the collected cat hair and can be a product that fits within the environment. In theory, the design was to be more effective than the average lint roller as it allows for less movement for the user and collection in each direction, however, the model didn’t roll around as much. The final model produced didn’t completely ease worry for the client, due to the small collection of the cat hair and that the product wasn’t completely automated.